Successful Development of KRCONN USB3.1 IP68 Waterproof Type-C Base

Successful Development of KRCONN USB3.1 IP68 Waterproof Type-C Base

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp;Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp;

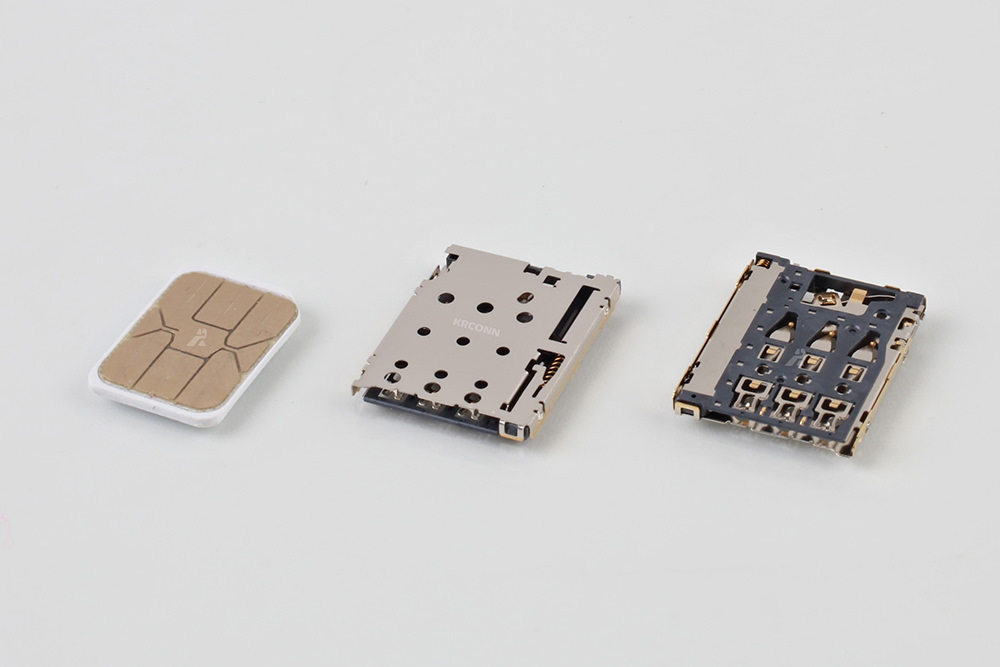

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TWR01-32122402-1124pin (tongue leak-double shell welding IPX8 waterproof) plate base)

Nbsp; & nbsp; & USB TYPE-C is popular today, the demand is more and more diversified. Against this background, KRCONN developed waterproof socket connectors based on USB TypeC and began to sell them. KRCONN/Jingrui started to lay out waterproof TYPE-C as early as 2014. After years of technical accumulation, TWR01-32122402-11, a large IPX8 waterproof TYPE-C base, was finally developed. This solution can be used in mobile phones, computers and other high-grade waterproof electronic products.

: & nbsp; summary & nbsp;

According to market demand, KRCONN has developed IPX8 waterproof TYPE-C base, which can replace JAE, TE and Amphenol waterproof TYPE-C base perfectly. It is more stable to use double iron shell + laser spot welding. It is difficult to form Limu in one. The waterproof rubber ring formed directly on the iron shell has better and more reliable bonding. TYPE-C tail height is slightly lower than the frame mouth, providing customers with compact interior space with more diverse structural design waterproof connectors (IPX7 or above) because of the sealing (resin seal) structure, waterproof is generally the basic function, and sometimes there may be leakage in some small gaps due to the heat of reflux. For this reason, the product takes into account the heat resistance defects of connectors, instead of using sealing rings, using a separate embedded structure to achieve waterproof function. Therefore, after reflux, it can also meet the high demand waterproof performance of IPX8 (immersion 1.5 & nbsp; & nbsp; 30) and can be safely used in various high-end models.

: advantages

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp;Nbsp; waterproof socket based on USB Type-CNbsp; after reflux, IPX8 (immersion 1.5m 30) can be waterproof.Supporting maximum 5A high current (USB Power Delivery Revision 3.0)Nbsp; to meet more structural design

:: Application Market

Smart phones, computers, digital cameras, VR (virtual reality)/AR (augmented reality), printers, and others

:: General specification

Nbsp; & nbsp; & nbsp; & nbsp; form:

TYPE-C socket connector

Nbsp; & nbsp; & nbsp; & nbsp; material number:

TCR43-32112402-11

Nbsp; & nbsp; contact morphology:

Four corners DIP

Nbsp; & nbsp; central height:

Nbsp; & nbsp; rated current:

Max 5A

Nbsp; & nbsp; & nbsp; & nbsp; number of needles:

24 needles

Nbsp; & nbsp; rated voltage:

AC20V r.m.s.

Nbsp; & nbsp; contact resistance:

Initial 40 m_below

Nbsp; & nbsp; withstand voltage:

AC 40V r.m.s. (1 minute)

Nbsp; & nbsp; insulation resistance:

More than 100 M_

Nbsp; using temperature range:

- 30 +80 65507

Nbsp; & nbsp; insertion life:

The 10000 time

Nbsp; drawing links & nbsp;

2017-10-28

KRCONN tongue dew series TYPE-C base

Nbsp; & nbsp; & nbsp; & nbsp; TYPE. C 2.0 sink plate 1.6 16pin double shell laser welding, tongue leakage

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & with the outbreak of the full screen, the TYPE-C space left in the mobile phone is becoming smaller and smaller.

2019-01-15

KRCONN Successfully Develops Stamping Cator

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; Stainless steel stamping process split three-choice dicarbot-short ST32-01-003

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp;

Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & stainless steel stamping process cato, which is well developed, can be applied in many fields to meet different customers

Summary: nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; Sagacity has been focusing on the field of SIM card, and has developed many different types of SIM card before and after. In the period of smartphone outbreak, smart follow the trend, has developed a number of combinational SIM card. But the SIM cards developed by R&D personnel day and night are always in trouble with customers, which is largely attributed to Kato. As the saying goes, if a horse is well equipped with saddles, in the high-precision product of the card holder, the matching production of the card holder and the card holder can achieve the best effect. The SIM cartridge body manufactured by this sophisticated research and development adopts innovative stamping style. The cartridge body is stamped out by using 304 material of high-speed stamping machine, then spot welding and oxidation are carried out. Compared with CNC process, the CNC process of Cato has a beautiful appearance, but its processing cost is high and efficiency is low. CNC generally processed materials are aluminum, soft texture. Compared with the CNC process, the powder metallurgical cator is harder, but it needs to open the mould to produce and manufacture, and can not produce integrated products, so it needs to weld the body and the outside of the cator. Of course, there is also a kind of plastic plus steel sheet once Molding forming cartridge. The advantages of this kind of cartridge are high efficiency and low cost, but when making the cartridge, it still needs to be welded with the same cartridge and appearance as powder metallurgy.

: & nbsp; comparison with other processes: & nbsp; Drawing connection